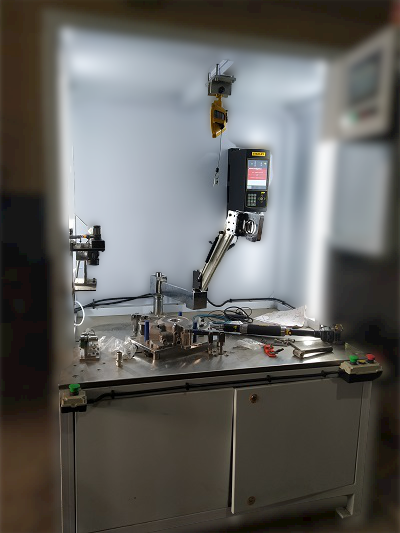

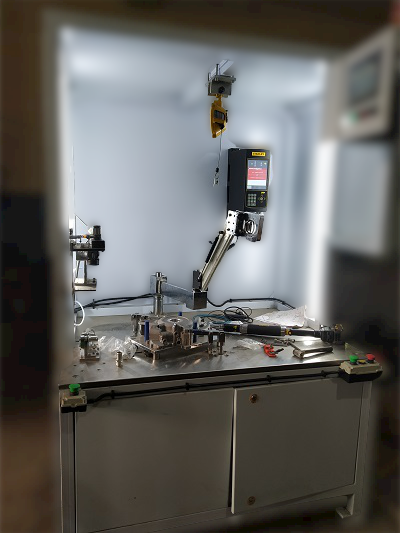

Leakage Testing Machine

Leak testing is a procedure to check any defect or leakage in any system which can be done by many methods and the test ensures the integrity and proper functioning of some machines. The UMR technology is the manufacturer, trader, and supplier of these leak testing machines to meet their client’s requirements. There are various techniques by which the detection of leakage is possible in any machine like air decay testing, helium leak testing, high vacuum methods, and water submersed but all of them has the application in particular condition with specific machines. We offer almost every major and minor machine in the arena of automation, water treatment and spare parts of bikes along with these leak detection machines whether it is 1–dry leak testing or 2-wet leak testing at the most affordable money value.

We have extensive range of leakage testing machines that are highly demanded over the nation in different industries to control the leakage of various types of machines and keeping their integrity on the top. Our offered machines follow international standards and are made with the aid of modern tools and advance technology by the expert professional who has great efficiency in the arena. The company even provides a customized solution for the testing machine as per the facility required or the specification given by the client in a proper frame of time.

Our product combines vast experience with a modular approach of techniques. The best and updated modern data capture methods and proven and advanced software techniques are engineered into our production environment to provide reliable and easily maintainable equipment that we built under expert supervision. Apart from that our Leak Test Machines have the capability of challenging tiniest leakages with the highest accuracy with pressure drop & void methods. Further, we are explaining a few of the leak testing methods which are an important specification to consider when choosing leak testing equipment

Bubble testing is used for the machines which do not need high sensitivity. A pressurized test object is submerged in a water tank so that the emergence of bubbles indicates a leak.

Colorimetric development uses a chemical developer which reacts with the leaking fluid, which causes a visible color change to occur at the place of leakage.

Leak testing equipment that uses electronic gas detection pressurizes the test object with a tracer gas so that a sniffer probe can be used to find the leak. Mass flow devices direct the leakage across a heating element. The temperature change produces an output voltage proportional to mass flow. Helium leak detection takes place with mass spectrometers. Leak testing equipment that is designed to detect hydrogen leaks is also available. Ultrasonic leak detection involves the turbulent flow of a fluid across a pressure boundary to create acoustic waves. These waves are transmitted through the medium of the fluid itself, through the containment structure, or through the air surrounding the containment structure. Leak testing equipment that uses other test methods is also available at UMR Technology.

Features of our leak testing machines:

- Longer service life

- Efficient working

- Low-maintenance

- Rugged

- Abrasion-resistant

- Fine finish

- Easy installation

.png)