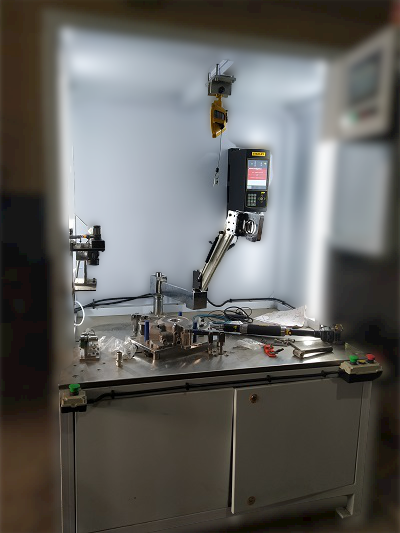

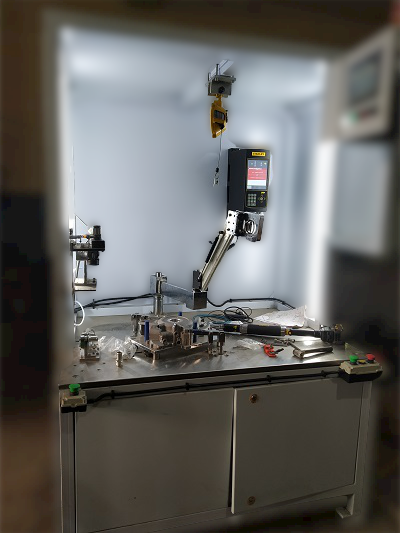

Welding Special Purpose Machine

Welding Special Purpose Machine:

UMR Technology deals in the manufacturing of a wide range of welding special purpose machines that are usable when shapes are a bit complicated. We design the customized solutions of these machines so that can help end-users in their various applications specifically as per their demand. For the varied production environment and industrial application, we manufacture these machines with the utmost accuracy and proper efficiency. Apart from that, we design various other machines like linear, rotary, and profile welding machinery. The product created can optimize the production rate and quality of the machine that can find its use in many industrial areas. We take into account the component profile and welding process to provide our clients with multi-axis, semi-automatic welding equipment. We optimize the manufacturing process flow, the products can minimize the need for manual handling of heavy jobs owing to the applicable welding fixtures that are fitted along our Welding SPM.

When some industry searches for super specialty machines, there is a wide spectrum of such machines. As a consumer, they should have to be clear and specific about the requirement specs first. Just by getting clear requirement specifications we can manufacture the best and effective solution for the demand of the client, and can customize it too. It depends on the user requirement. When you hire a vendor, it is important that an experienced vendor is preferred and we are stable in the concerned arena from many years with a wide base of clientele who have great testimonials for our services.

The machine-generated or designed by our production unit offers the major advantages of automated welding systems: enhanced welding efficiency, improved production, lower scrap, and reduced labor costs. Our automated welding systems ensure weld integrity through electronic weld process controllers. Our Semi-automated and fully automated systems increase the output of the welding process by reducing human efforts. Convincingly created Welding automation system of UMR technology easily surpasses a skilled manual welder with reduced setup time and higher welding speeds.

Features of our welding SPM

• Manufacture as per Clients' demand.

• Fully automatic / Semi-automatic welding SPM

• Reduces production lead time

• Better product quality SPM machine

• Designed with modernized techniques

• Highly upgraded

• Less use of energy

• Saves the labor cost.

• Best bearing arrangements.

• High end cutting solutions

• Great perfection

• Better efficiency

• End-user friendly

Application arena for our welding SPM

• In the manufacturing of various automobile components.

• Many accessories for two/four wheeler vehicles cab be generated through them.

• Road Rollers or any other similar cylindrical components

• In Hydraulic cylinders.

• In Pipe to Flange SPM welding.

• It is a turntable with TIG / MIG Torch Auto welding sequence configuration.

• Complete LPG cylinder project including system management

• Machining equipment for domestic / API pipes with automated handling system

• The creation of unique nature automobile components can be done by the use of welding SPM.

- Various specific wheel component accessories for two-wheelers and four-wheelers.

• Idler roller welding conveyor automatic loading and unloading systems

• It can be used in the Rebuilding setup for Road Rollers or any other similar cylindrical components.

.png)