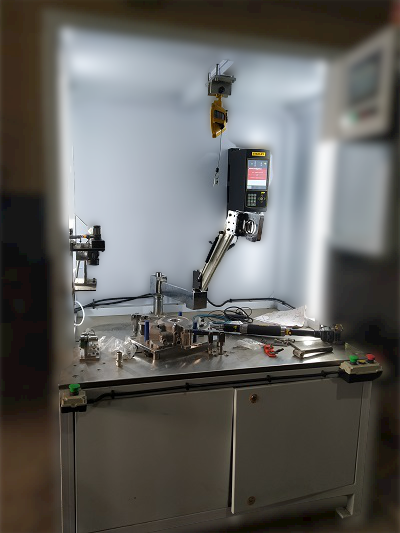

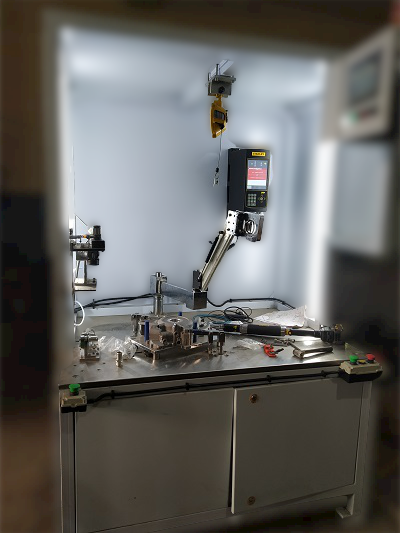

Hydro Pressing SPM

Hydro press SPM:

UMR Technology is a World Class industrial engineering manufacturing firm that specializes in the complete marketing and manufacturing of a wide range of machines which are usable in different industries, the highly efficient machines generated are SPM, hydro-pneumatic press, hydraulic fixtures, robotic fixtures, hydro press SPM and many more. A hydraulic press has a lot of application in various companies and works on the principle of Pascal’s law, as per this law when pressure is applied to a confined fluid, the pressure change takes place throughout the entire fluid. Within the hydraulic press, there is a piston that works as a pump,that provides a required mechanical force to a particular area of the sample. There is another pistol in it that has a larger area and produces a larger mechanical force. A hydraulic press uses a hydraulic cylinder to produce a compressive mechanical force. Apart from these pistols, it consists of a place where the sample is placed for pressing the sample. The use of hydraulic presses has considerably increased the speed. Our Hydro press SPM is versatile instrument and can be used to prepare a large range of samples. There is also a lot of flexibility in operation, with various speeds, forces, directions, and pressure available.

The machine offers more intricate shapes and is highly economical with material that is used and can be beneficial for large manufacturing units in which compressing of material is needed on large scale. UMR is recognized and leading among professionals in the arena of manufacturing these pressing machines in the market with the most positive testimonials of a wide base of clientele.

The hard-working and passionate team of UMR Technology dedicates their labor to get such a level of satisfaction from clientele. Today there are many industries in a market where the use of these machines is mandatory like bulldozers, forklifts, aircraft, and spacecraft and our quality of the product has already put the impression in the market. The great functionality of our pressing machine is the result of our dedicated team. its internal parts and the hydraulic press which is designed to assemble is used to check first that all of them are functioning properly or not, If they are functioning then we deliver the product or if it is not then repeat the process and find the area where the problem is occur and solve the problem after solving the problem again check the whole working of the machine after that deliver the machine to the client. For client satisfaction, the machine is also checked at the plant of the client and tells him/her the way how it works.

Features of our pressing machine

• Reliability

• Excellent performance

• Saves electricity

• Uses optimize floor space

• Available in various frames like h-frame, c-frame, four-pillar, rolling table press, etc.

• Customized productions

• Die cushions

• Ejectors

• Blank holder

• Mechanical knock-outs

• Shock absorbers

• Quick die change systems

• Coil feed lines

• Transfer systems

• Loaders, unloaders, rotary / linear tables, etc.

Applications: Our wide range of pressing machines are being used for every operation like DEEP DRAWING, COLD FORGING, RIVETING, BLANKING, PRESS FIT (ASSEMBLY LINE), COINING, HEADING, STRAIGHTENING, FORMING & Other Applications also in many different manufacturing unit or companies.

.png)